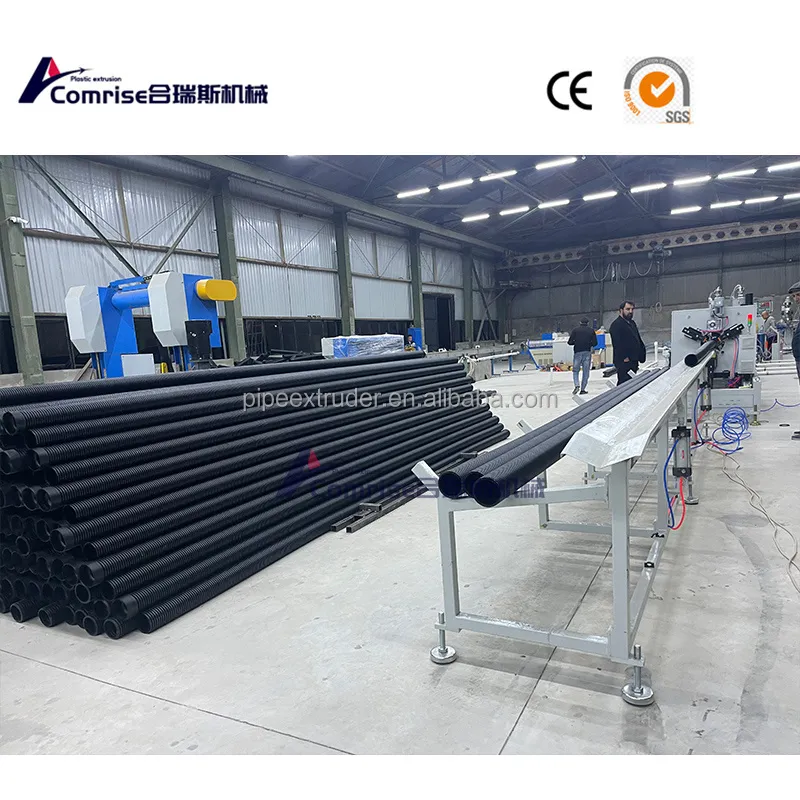

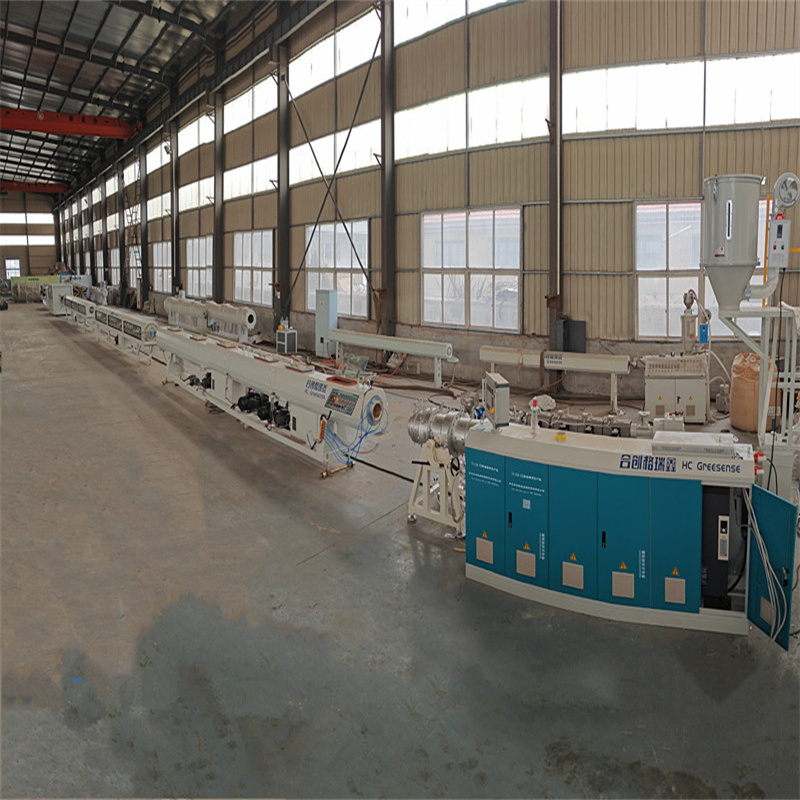

Potrubie DWC

Odoslať dopyt

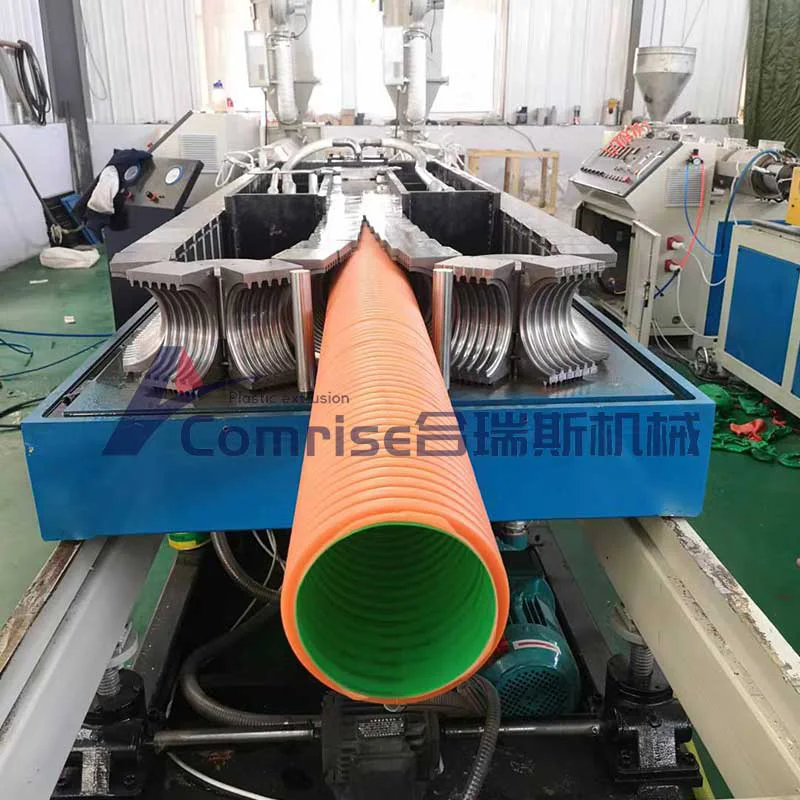

DWC Pipe Machine Iron Mold vs. Aluminum Mold

1. Iron Mold:

- Material: Made of high-quality cast iron.

- Durability: Less durable compared to aluminum molds

- Heat Retention: Lower heat retention, which may slightly reduce production speed.

- Cost: cost-effective than aluminum molds.

- Applications: Suitable for small to medium-scale production and applications where cost efficiency is a priority.

2. Aluminum Mold:

- Material: Made of lightweight aluminum alloy.

- Durability: Highly durable and resistant to wear, making it suitable for long-term use.

- Heat Retention: Better heat retention, which can improve production efficiency.

- Cost: Generally more expensive than iron molds.

- Applications: Ideal for large-scale production and heavy-duty applications where high precision and durability are required.

DWC Pipe Machine Production Speed

- Iron Mold:

- Can produce pipes at a rate of 1-3 meters per minute, depending on the machine configuration and pipe diameter.

- Aluminum Mold:

- Typically produces pipes at a rate of 4-8 meters per minute, depending on the machine and pipe specifications.

GET A QUOTATION NOW

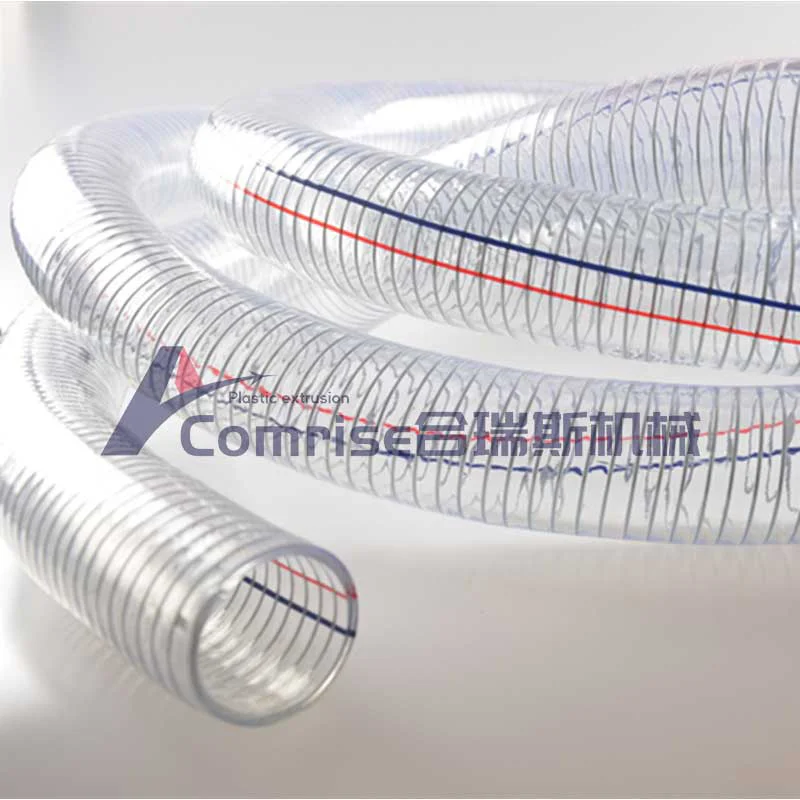

DWC Pipe Machine Applications

- Drainage Systems: Used in municipal and industrial drainage systems due to their high strength and corrosion resistance.

- Sewage Systems: Ideal for transporting wastewater and sewage in urban and rural areas.

- Cable Protection: Provides robust protection for underground cables and communication lines.

- Agricultural Drainage: Used in agricultural fields for efficient water management.

- Road and Highway Construction: Employed in road drainage systems to prevent waterlogging.

Advantages of DWC Pipe Machine

- High Efficiency: Automated production process ensures consistent output.

- Versatility: Can produce pipes of various diameters and lengths.

- Cost-Effective: Reduces material waste and labor costs.

- Durability: Produces pipes with excellent mechanical properties and long service life.

DWC Pipe Machine is a versatile and efficient solution for manufacturing double-wall corrugated pipes. The choice between iron and aluminum molds depends on production scale, budget, and specific application requirements.